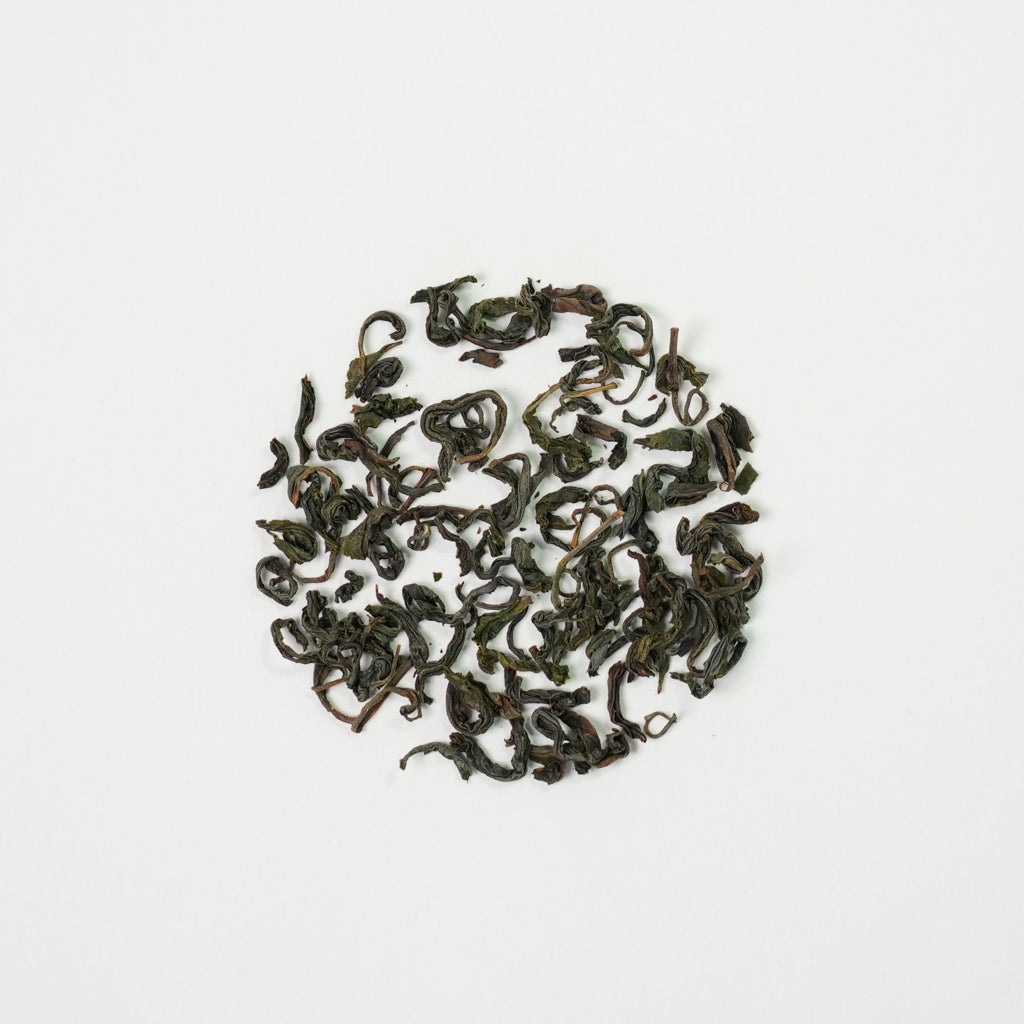

Do you know about Japanese Oolong tea?

You may know, the semi-fermented teas are generally all lumped together under Oolong tea, but in Taiwan, they maintain two distinct categories: Oolong and Baozhong tea. Japanese oolong tea is categorized more like Baozhong tea.

Plucking is conducted in later part of June as SF. FF leaves generally flexible but thick and have a pale green color while SF has a bit stronger aroma but less flexible and less savory umami taste.

As a general rule, plucked leaves are processed the very same day.

The processing follows as the steps mentioned in the below while I have no idea about that of Chinese oolong tea.

1) Sun-dried withering

Tea leaves are spread across a tarp at about 0.6~1.0kg per 1m² and are regularly stirred to ensure even withering. The optimal leaf temperature is 30~40℃. If leaves heat above 40℃, gauze netting is used to create some shading. Leaf moisture is monitored as withering continues, usually for 10~20 min or possibly 30~40min under cloudy conditions.

Withering is sufficient when the first and second leaves on shoots lose their original luster and exhibit a ripple-like pattern, feel softer to the touch, and lose their raw grassy smell. Target is 8~16% weight reduction.

In case of rain, withering may be conducted with a hot-air withering machine.

2) Indoor withering

After tea leaves finish the initial withering process, they are brought indoors and spread out 0.6~1.0kg pr 1m² and left to sit for 1~2 hours. Then, the first round of very light stirring is performed for a duration of 1 minute.

Now, leaves continue to sit, and every 1~2 hours a 3~5min round of stirring is conducted. Each successive round of stirring will be more intense and last longer. However, this must be done carefully, because overly aggressive stirring can cause leaves to turn black and become bitter and astringent. Not enough stirring, and the leaves won't possess their distinctive aroma and remain raw and grassy smelling.

After the final round of stirring, leaves are again left to sit for 1-3 hours. Once they lose their raw smell and give off an invigorating aroma, they are ready for parching.

Target is 20~30% weight reduction.

3) Tea leaf parching

Parching is where the leaves are heated to kill off enzymes that cause oxidation. For non-fermented green teas, this is the very first process, but for semi-fermented teas, it takes place midway through production.

There are two main ways to perform parching when making oolong tea.

Using a Manual Parching Pan

First, the pan is heated to 160~180℃. The tea leaves are thrown in and parched until they start making loud popping sounds. When the leaves are taken out, they should feel soft when squeezed and have a pungent aroma. Left in too long, and the leaf edges can become burnt and stiff.

Using a Cylindrical Tea Parcher

Leaves are heated at 140~160℃ for 2~3min. Target is 38~48% weight reduction.

4) Tea rolling

Rolling is performed to ensure good leaf shape and improve leachability in hot water. This process should begin immediately after parching and lasts 10min.

After rolling, tea ball breaking is done to break apart any clumps they may have formed. This can also be performed by a machine, the tea ball breaker which can handle 400~600kg per hour.

5) Drying

The drying process uses high temperatures to kill off any remaining enzymes that survived parching. The goal is to fully eliminate raw grassy smell, bring out a subtle astringency, improve aroma, and lower moisture to 4%d.b. for optimal storage. If a dryer is used, it runs at 100℃ for about 30min.

The below is the precise info about where our oolong tea is cultivated.

The organic tea plantation is located in Isagawa, an area within Haruno village in the mountains of west Shizuoka within the greater Tenryu District.

Isagawa plantation is situated so that there is no chance of drift as it is a stand alone plantation surrounded by mountain views. The plantation itself runs from 300-540m in altitude.

Isagawa is referred to as “organic valley”, and Haruno village is a well-known mountain area for tea production, along with Tenryu and Mori in the same vicinity.

The teas of this area enjoy natural shading from nearby mountain slopes and natural fog / mist in the atmosphere.

Being in the mountains, coupled with the organic farmers’ cultivation know-how, there is no need to use chemical fertilizers or pesticides whatsoever.

There is no risk of bug damage during the 1st flush spring season due to the cooler climate and the farmers’ tea cultivation skills (timing of trimming leaves around seasonal changes, etc.) Osada Tea’s post refining factory and headquarters is in Mori-Machi- The Isagawa plantation is about a 40-minute drive north into the mountains and its size is 20ha.

Isagawa, where our organic tea plantation is, is located just along a main river water source (Fudou river and Tenryu Suikei River) that runs downstream to lower sectors from the mountain. This water is drinkable as is and you can fill your water bottle with the natural mountain water in some spots when hiking / driving up.

That said, one reasons our farmers do organic is to avoid the inevitable pollution and damage to the environment that the local natural environment would incur if we used chemical pesticides and fertilizers.

For this reason, Osada Tea encourages all farmers who are situated in natural environments where organic cultivation is possible, and are not yet making the switch, to do so. It is in their best interest to meet the growing organic demand, and is good for the local environment and future generations.

We are a tea house that looks to the future, new tea innovation, and we pay respect to nature- we wish to constantly improve in this area, and have achieved success thanks to Osada Tea’s post-refining “Shiage” skill coupled with the ingenuity of the organic tea farmers we are partnered with.

You may refer to the below site for the people behind our tea production.

![[OT-10] MATCHA KOSHUN (20g/0.7oz)](http://osadateajapan.com/cdn/shop/products/OT-10-1-_1.jpg?v=1673502690)

![[OT-04] MATCHA NONO (20g/0.7oz)](http://osadateajapan.com/cdn/shop/products/OT-04-1-_1.jpg?v=1673502659)

![[OT-11] MATCHA OKUMIDORI (20g/0.7oz)](http://osadateajapan.com/cdn/shop/products/OT-11-1-_1.jpg?v=1673502695)

![[OT-09] MATCHA SAEAKARI (20g/0.7oz)](http://osadateajapan.com/cdn/shop/products/OT-09-1-_1.jpg?v=1673502685)

![[OT-01] MATCHA SAMIDORI TEZUMI (20g/0.7oz)](http://osadateajapan.com/cdn/shop/products/OT-01-1-c6043315-f32d-4781-9b40-c902247ddea9-_1.jpg?v=1673502644)

![[OT-02] ORGANIC NISHI MATCHA OKUMIDORI (20g/0.7oz)](http://osadateajapan.com/cdn/shop/products/OT-02-1-_1.jpg?v=1673502648)

![[OT-05] ORGANIC NISHI MATCHA TSUYUHIKARI (20g/0.7oz)](http://osadateajapan.com/cdn/shop/products/OT-05-1-_1.jpg?v=1673502663)

![[OT-16] ORGANIC MATCHA HAMANASU (20g/0.7oz)](http://osadateajapan.com/cdn/shop/products/OT-16-1-_1.jpg?v=1673502719)

![[OT-61] ORGANIC BANCHA (30g/1oz)](http://osadateajapan.com/cdn/shop/products/OT-61-1-_1.jpg?v=1673502855)

![[OT-58] ORGANIC GENMAICHA (30g/1oz)](http://osadateajapan.com/cdn/shop/products/OT-58-1-_1.jpg?v=1673502847)

![[OT-34] ORGANIC GYOKURO OKUMIDORI (30g/1oz)](http://osadateajapan.com/cdn/shop/products/OT-34-1-_1.jpg?v=1673502781)

![[OT-33] ORGANIC GYOKURO SAEMIDORI (30g/1oz)](http://osadateajapan.com/cdn/shop/products/OT-33-1-_1.jpg?v=1673502778)

![[OT-56] ORGANIC MATCHA GENMAICHA (30g/1oz)](http://osadateajapan.com/cdn/shop/products/OT-56-1-_1.jpg?v=1673502843)

![[OT-43] ORGANIC OKUMIDORI KABUSECHA (30g/1oz)](http://osadateajapan.com/cdn/shop/products/OT-43-1-_1.jpg?v=1673502808)

![[OT-40] ORGANIC SENCHA AG TSUYUHIKARI (30g/1oz)](http://osadateajapan.com/cdn/shop/products/OT-40-1-_1.jpg?v=1673502801)

![[OT-39] ORGANIC SENCHA HIRAKI ASAMUSHI (30g/1oz)](http://osadateajapan.com/cdn/shop/products/OT-39-1-_1.jpg?v=1673502798)

![[OT-27] ORGANIC OOLONGTEA GOKOU (30g/1oz)](http://osadateajapan.com/cdn/shop/products/OT-27-1-_1.jpg?v=1673502764)

![[OT-28] ORGANIC OOLONGTEA KURASAWA (30g/1oz)](http://osadateajapan.com/cdn/shop/products/OT-28-1-1-_1.jpg?v=1673502766)

![[OT-31] ORGANIC OOLONGTEA SURUGAWASE SF (30g/1oz)](http://osadateajapan.com/cdn/shop/products/OT-31-1-_1.jpg?v=1673502772)

![[OT-26] ORGANIC OOLONGTEA TSUYUHIKARI (30g/1oz)](http://osadateajapan.com/cdn/shop/products/OT-26-1-_1.jpg?v=1673502762)

![[OT-29] ORGANIC OOLONGTEA ZAIRAI FF (30g/1oz)](http://osadateajapan.com/cdn/shop/products/OT-29-1-_1.jpg?v=1673502768)

![[OT-30] ORGANIC OOLONGTEA ZAIRAI SF (30g/1oz)](http://osadateajapan.com/cdn/shop/products/OT-30-1-_1.jpg?v=1673502770)

![[OT-04] MATCHA NONO (20g/0.7oz)](http://osadateajapan.com/cdn/shop/products/OT-04-5.jpg?v=1671249709)

![[OT-01] MATCHA SAMIDORI TEZUMI (20g/0.7oz)](http://osadateajapan.com/cdn/shop/products/OT-01-5_504055a4-6c55-440d-af84-58b806fd5bf5.jpg?v=1671136783)

![[OT-32] ORGANIC BLACKTEA BENIFUUKI (30g/1oz)](http://osadateajapan.com/cdn/shop/products/OT-32-1-_1.jpg?v=1673502774)

![[OT-32] ORGANIC BLACKTEA BENIFUUKI (30g/1oz)](http://osadateajapan.com/cdn/shop/products/OT-32-5.jpg?v=1671250277)

![[OT-50] ORGANIC KAMAIRICHA FF (30g/1oz)](http://osadateajapan.com/cdn/shop/products/OT-50-1-_1.jpg?v=1673502826)

![[OT-50] ORGANIC KAMAIRICHA FF (30g/1oz)](http://osadateajapan.com/cdn/shop/products/OT-50-5.jpg?v=1671250984)

![[OT-14] ORGANIC MATCHA KAKITSUBATA (20g/0.7oz)](http://osadateajapan.com/cdn/shop/products/OT-14-1-_1.jpg?v=1673502708)

![[OT-14] ORGANIC MATCHA KAKITSUBATA (20g/0.7oz)](http://osadateajapan.com/cdn/shop/products/OT-14-5.jpg?v=1671249965)

![[OT-07] ORGANIC MATCHA KOIAI (20g/0.7oz)](http://osadateajapan.com/cdn/shop/products/OT-07-1-_1.jpg?v=1673502675)

![[OT-07] ORGANIC MATCHA KOIAI (20g/0.7oz)](http://osadateajapan.com/cdn/shop/products/OT-07-5.jpg?v=1671249758)

![[OT-27] ORGANIC OOLONGTEA GOKOU (30g/1oz)](http://osadateajapan.com/cdn/shop/products/OT-27-5.jpg?v=1671250166)